For free test drive or some more detailed information please do not hesitate to contact us.

Automated ordering and replenishment is crucial in each big warehouse and company. Nadii helps you with these tasks and minimalises precious time, which your staff has to spend on routine ordering and planning.

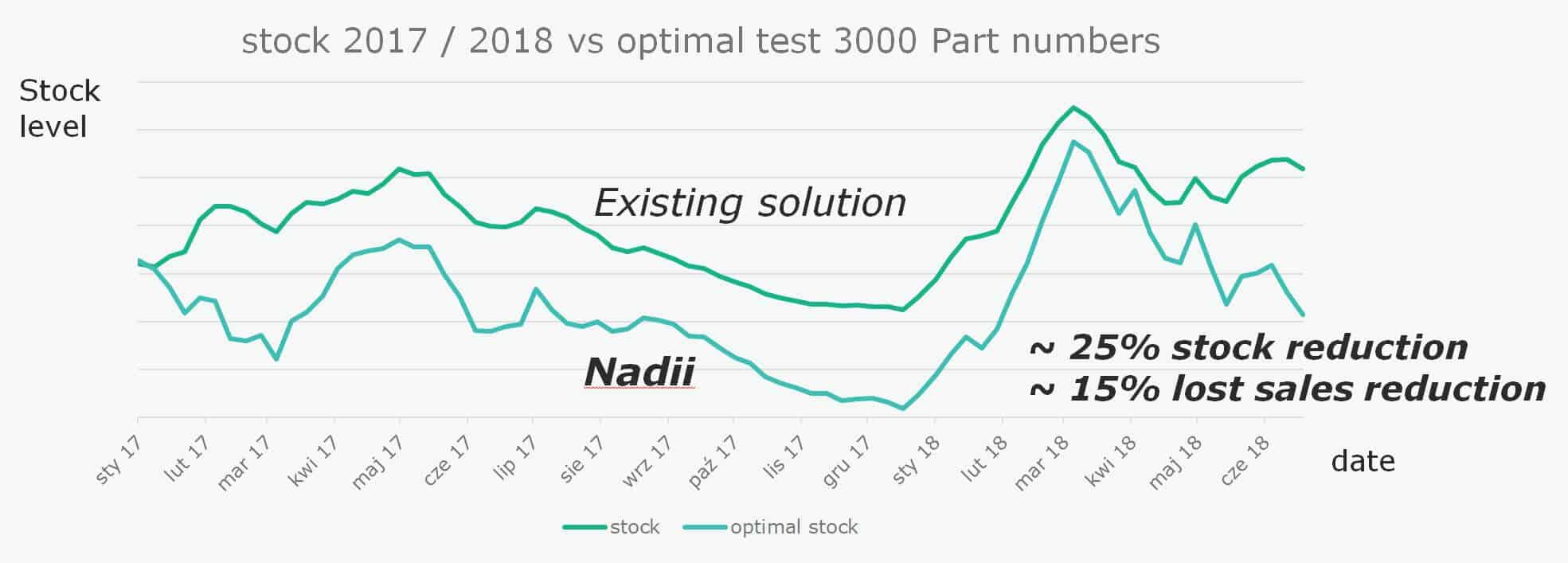

Nadii features automated replenishment system, which is based on robust and very precise demand and lead times forecasts.

Nadii understands your logistics costs, network and product criticality

Handling and storage costs between a box of pens and a printer are not the same. And availability of high margin best-seller is not as important as some low-end replacement. Sometimes customers can wait until next day for delivery from a regional warehouse, but sometimes they need it at Point of Sales.

This makes stock ordering and movements decisions complex. That’s why they should be automatically adapted to YOUR criteria for each part number every day. Then users will be able to look over them. Check out yourself how Nadii does it with any of your data!

Valuable feedback

Nadii scores permanently his replenishment decisions to assess performance and alert. Since scoring also applies to changes inputed by your staff, Nadii in turn gives them feedback on the pertinence of their choices. In addition to that the software will look for families in your database and even help cleaning master data.

Clear-cut benefits for the customer

Nadii automatic replenishment system has cut our customers’ stock levels by up to 40%, out-of-stocks by as much as 40% and no-needs stock by up to 50%. These are really astonishing values which provides clear-cut benefits for the customer.

Features which make a real difference

Nadii creates automatic orders to your suppliers, internal stock movements between your warehouses, forecasts sales and operations planning very precisely and takes care of tactical planning for your factories and warehouses.

The advantages of AI-driven solutions

The system uses AI-driven solutions to achieve detailed and best possible results even if there is little history or some values are missing. Sometimes Nadii may warn your staff when he feels that some very important piece of information is missing or having trouble with forecasting, but in 99% situations he makes fully autonomous decisions.

The importance of automated ordering frequency adjustment

What’s also worth mentioning Nadii deals with automated ordering frequency adjustment, because he automatically processes the economic equation and suggests the optimal ordering frequency. That is very important when demand, logistics costs, factory downtime and minimum order quantity vary. In such situations optimising the frequency of ordering by using traditional methods is really hard to manage.

Logistics costs optimisation

Nadii can automatically adapt his stock policy to ensure full availability of your critical products, while being aggressive on stock levels with less critical products. Therefore you can easily optimise your logistcs costs and save lots of time.

Anticipative vs reactive supply chain management

Nadii spots and warns ahead of time against different issues like for example abnormally high/low orders, new product without dedicated supplier etc., so your staff can deal with them, before they become problematic.