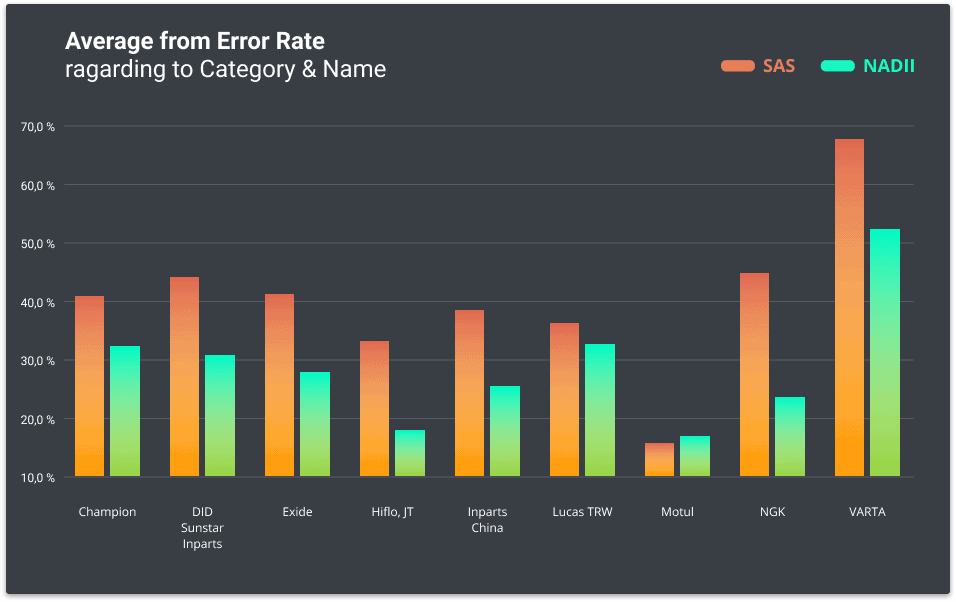

Take a look at the images displayed below. The first chart shows average values related to error rate. Highest bars indicate highest error rates, so the lower the better. Nadii results are represented by green bars.

Demand & lead times forecasting is essential for proper supply chain management and successful inventory planning.

AI-driven algorithms and machine learning engine guarantee precise forecasts, which help you make the most accurate inventory decisions.

Have you ever thought how does your existing system address varying lead times?

If your system considers them as a fixed parameter, it is probably set to maximum value. Unfortunately this is not reasonable, because most suppliers, transport companies and factories suffer as much as you from seasonality / breaks / low runner availability and other similar factors. All people who have some experience in supply chain management are aware that lead times vary a lot throughout the year. Nadii makes a huge difference by automatically forecasting and adapting lead times for each part number, location and supplier all year long.

How Nadii is able to predict furture sales and demand?

Nadii benefits from the advantages of machine learning and AI driven technology to help you make the most optimal decisions. He also shows that Artificial Intelligence can cooperate with humans, so that both can focus on what they are best at.

Traditional and modern forecasting methods

The application mixes traditional robust statistical forecasting methods with machine learning dedicated approach and focus on supply chain. The model is fine-tuned to specific customer data and auto-adaptive for unplanned events. It dynamically chooses the best fit for a given item or supplier at a given location providing performance today as well as for the upcoming years.

Why algorithms are so important and helpful?

Over 200 algorithms use their own traits to integrate and analyse important external features including product families, geographical information, unreliable suppliers, holiday breaks etc. Moreover they know how to deal with the missing values and extract trends from external data. These algorithms are also auto-adaptive and they draw the right conclusions from the wrong turns.

How can we compare Nadii performance with SAS software results?

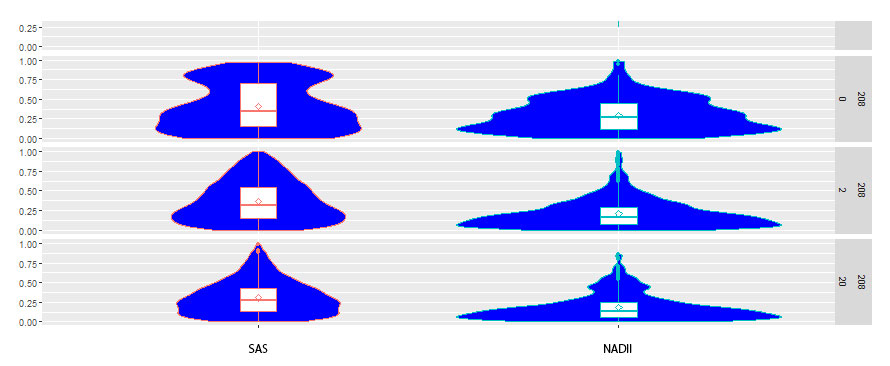

The second image shows violin plots representing demand forecast results for part numbers vs real demand. The larger the plot is at a given Y axis, the more part numbers have error in forecasting. The perfect violin plot is fat at low error rate and thin at high error rate. Two violin plots displayed at the bottom of the image show the difference between SAS and Nadii very well and these plots represent important key high runners.

Outstanding precision even in case of brand-new products

As a result demand and lead times forecasting is very precise not only for well-known products, but even in case of new items, which have been available for just few weeks. It makes a particular difference when businesses face scale, volatility or complexity.

Sales up, inventory down

All software choices can be easily interpreted, because it gives insights to users. With Nadii support you will avoid unnecessary inventory movements and increase inventory turnover rates. This way you will save a lot of precious time and money.